FORMULATION AND MANUFACTURE OF FUNCTIONAL FOODS

FORMULATION AND MANUFACTURE OF FUNCTIONAL FOODS

The quality of a functional food product is determined by the formulation process. A good line of functional foods that bring many benefits to people needs to have a superior and breakthrough formula. Therefore, to ensure your health, you should only choose truly quality functional foods with good formulas from quality manufacturers.

The following article will share with you the process of building functional food formulas so that everyone can better understand and choose reputable, quality units.

Are functional foods good?

Functional foods are foods used to support the function of organs and parts of the human body. With the role of nutritional supplements, creating a comfortable state for the body. At the same time, it helps increase resistance, reducing the risk of disease.

Are functional foods good?

Recent studies have shown the potential application of functional foods in various pathological complications. Some of the pathologies include diabetes, atherosclerosis, cardiovascular disease, cancer, and neurological diseases.

Most of the bioactives have antioxidant activity with the ability to resist changes in redox state. Therefore, they are considered as a source of healthy health promotion. Especially for preventing life-threatening diseases such as diabetes, kidney infections, and disorders related to the digestive tract.

Pharmaceutical, nutritional and functional food companies are aware of the changing trend due to the advantages of these compounds. But creating a functional food is not simply adding a series of biologically active ingredients to the product. Formulating and preparing functional foods includes steps that require investment in knowledge of experts. In addition, it requires a harmonious combination of quality raw materials. Seriousness in the process of evaluating the effectiveness of the product.

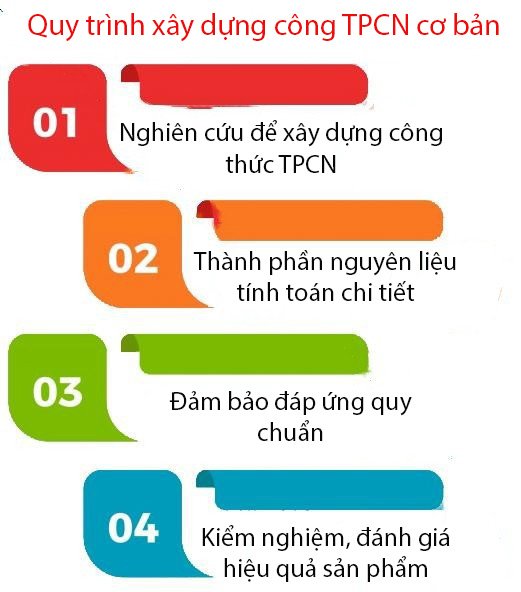

Process of formula development and preparation of dietary supplements

The process of formulating and preparing functional foods includes the following basic steps:

Research additional ingredients in the formula

Important issues in the formulation of dietary supplements include discovering which ingredients to use and what claims can be made. The ingredients a company chooses to include in its dietary supplement can be critical to the success of its product in the marketplace. Some of the active ingredients currently used by manufacturers are probiotics. Or herbal extracts, plant sterols. Other possible uses include functional fats, antioxidants, and amino acids.

Research additional ingredients in the formula

Build product formula

The product research and development department of each manufacturing unit will base on basic research. Firstly, based on the additional ingredients to come up with a preliminary formula to create the product, including: the main ingredients that create the product's uses, the source of raw materials providing the main active ingredients, uses, users, etc. Based on the established formula, search for documents related to the ingredients to mix in the appropriate ratio, ensuring the uses of the active ingredients when combined in the same formula, maximizing the effectiveness of the product's uses.

Selection of raw materials and dosage forms

Raw materials for the production of functional foods are extremely diverse and abundant, from origin to supplier. However, the selection of raw materials must ensure strict conditions on food safety, origin, active ingredient content, especially must be in the list permitted by the Ministry of Health. Natural active ingredients added to functional foods are often derived from plants and herbs, which have proven pharmacological properties. In addition, products of microbial fermentation also contribute to the diversity of this raw material.

Selection of raw materials and dosage forms

Functional foods can be prepared in many forms: tablets, capsules, granules, syrups, solutions, etc. Each form has its own advantages and disadvantages. Based on the established formula and the source of raw materials determined after research and survey, choosing the form of preparation is the next important step that determines the quality and effectiveness of the product.

Evaluate product effectiveness and safety

Before being put into production, functional food products must be evaluated for safety and clinical effectiveness. Safety evaluation indicators include microbiological indicators, heavy metal indicators, toxins, etc. The effectiveness of the product is demonstrated through physical and chemical indicators, nutritional indicators and biological activity of the main ingredients in the product. Product evaluation includes research on stability, shelf life and effects of the ingredients present in the product. Evaluation methods must be accurate and reliable, according to Vietnamese standards and those of other countries in the world such as TCVN, ISO, US Pharmacopoeia, etc.

Process of building dietary supplement formula

Why should you choose a unit to build dietary supplement formulas?

Formulating and preparing functional foods is a process that requires a team of highly qualified researchers with experience in the field of research and production of functional foods. In addition, the machinery and equipment system must meet strict requirements during the production and analysis of products.

NANOFRANCE high-tech DP manufacturing company with an experienced R&D team, a new factory complex with modern advanced equipment meeting the functional food production technology with safety and efficiency criteria, is currently one of the leading prestigious factories in the field of research and production of functional foods in the Vietnamese market.

With many years of experience in the field of functional food production, NANOFRANCE Company hopes to bring trust and the best products to consumers.