SUBLIMATION DRYING TECHNOLOGY

Freeze drying is currently the most advanced technology in post-harvest food processing because it helps retains maximum color, structure and nutritional value of food . Nanofrance is one of the pioneers in applying freeze-drying technology to the production of macrobiotic products and vegetable and fruit essence products.

- Freeze drying concept

Freeze drying is a process in which the product is dried at low temperature in a vacuum environment. The water in the sample is first frozen into a solid and then removed directly by converting the ice directly into vapor without going through the liquid phase.

Freeze drying is often used in medicine to dry herbs and ingredients for the production of functional foods such as cordyceps, lingzhi mushrooms, bird's nest, vegetable and fruit powder, etc.

Freeze dried cordyceps

Freeze dried vegetables

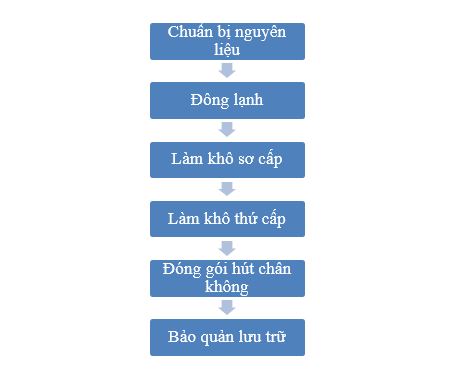

- Freeze drying process

Prepare ingredients

At this stage, the raw materials are carefully prepared with corresponding technical requirements. Depending on the type of raw materials, it will be necessary to add some appropriate additives.

Freezing

During this stage the material can be flash frozen or ultra-flash frozen. Flash freezing agents such as dry ice, methanol or liquid nitrogen are used. Typically, the freezing temperature is between -50°C and -80°C. This stage is the most important in the whole process, as the product can be damaged if not done properly.

Primary drying

At this stage, the pressure in the drying environment is reduced to vacuum pressure. The amount of heat supplied is precisely calculated so that the ice crystals sublimate without passing through the liquid phase. At this stage, 90% of the moisture in the raw material is removed.

Secondary drying

The secondary drying stage is the stage of evaporating the remaining moisture from the previous stage. In this stage, the temperature will be gradually increased and can be >0°C. At the end of the process, the moisture content in the raw material is only about 1% - 4%.

Vacuum packing

After freeze-drying, food will be vacuum-packed to prevent moisture and oxidation.

Storage and preservation

Packaged food will continue to be stored at cold temperatures.

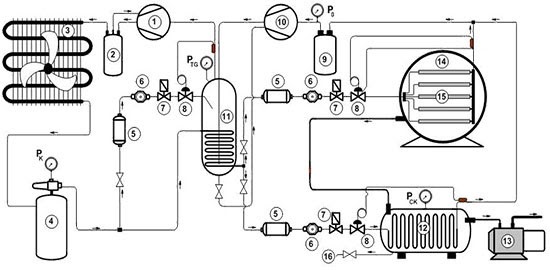

- Working principle

The basic principle in the freeze-drying process is sublimation, water will change directly from a solid (ice) to a gas (vapor). Like evaporation, sublimation occurs when a molecule receives enough energy to break apart the molecules around it.

There are two main factors that determine which state a substance will change into (solid, liquid or gas), which are temperature and atmospheric pressure. If the conditions are not met, that state of the substance cannot exist. The chart below shows the pressure and temperature values required for the different states of water.

You can see on the diagram that water can be a liquid at 1 atmosphere of pressure and the temperature is between the freezing point of 0 degrees Celsius and the boiling point of 100 degrees Celsius. But if you raise the temperature above 32 degrees Fahrenheit and keep the atmospheric pressure below 0.6 atmospheres, the water is warm enough to freeze, but not pressurized enough to form a liquid. It becomes a gas.

Principle of freeze drying

- Advantages of freeze drying method

The unique advantage of freeze drying is that the samples are kept at low temperatures and remain frozen throughout the drying process, thus preserving the original color and flavor of the raw materials and preserving all heat-labile components (proteins, vitamins, minerals, etc.). The dried products can be stored for a long time without changing their composition or being contaminated with microorganisms.

- Products manufactured at Nanofrance have applied freeze-drying technology.

Nanofrance High-Tech DP Production Co., Ltd. is always a pioneer in absorbing and applying new production technologies. Therefore, freeze-dried raw materials have been applied in functional foods produced at Nanofrance. Some typical products include: Hogi pumpkin essence, Hogi fish mint essence, Hogi red amaranth essence, Vegetables essences Sgreen, Green BB rice cereal...