NANOFRANCE FUNCTIONAL FOOD PRODUCTION PROCESS

Modern lifestyles mean that not everyone manages to eat a healthy diet. In Europe, dietary surveys have suggested that there are suboptimal intakes of some micronutrients. The EU-funded EURRECA project has found inadequate intakes of vitamin C, vitamin D, folic acid, calcium, selenium and iodine. Iron deficiency in young women also increases the risk of low birth weight, iron deficiency and mental retardation in children. Recent research suggests that 50–70% of Europeans have poor vitamin D status. However, daily food intake is not sufficient, so functional foods have emerged to help address this urgent problem.

What are functional foods?

Dietary supplements, or health foods, are products that provide nutrients that may not be consumed in adequate amounts through daily food intake. Dietary supplements can be vitamins, minerals, amino acids, fatty acids, and other substances distributed in the form of pills, tablets, capsules, liquids, etc.

|

|

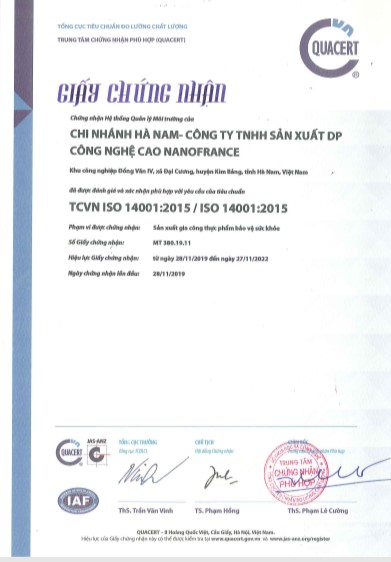

NANOFRANCE is one of the pioneers in investing in the most modern machinery, equipment and technology in the production of functional foods to meet the needs of functional food processing and become a reliable partner .

NANOFRANCE is one of the first 10 functional food manufacturing companies recognized by authorities as qualified to produce functional foods and meet GMP and ISO 9001-2015 standards for the production and trading of functional foods.

|

|

Being a pioneer in applying the most advanced dietary supplement production technologies in the world, Nanofrance's products must go through a professional, closed production process and be subject to very strict quality control.

NANOFRANCE is always the brand trusted and chosen by partners because of the following 6 outstanding strengths:

- Modern production technology and synchronous equipment

Production technology is the most important thing for a functional food processing unit. At NANOFRANCE, 100% of machinery and production technology are transferred from the most advanced countries in the world in the production of functional foods.

The production zones and functional rooms at the factory are extremely modern, not only meeting the standards set by the Ministry of Health but also ensuring international standards.

Raw materials in stock will be sampled for testing. Only when 100% of input materials are of guaranteed quality will production begin.

The formula research and development department is also invested in machinery and analytical equipment, and testing effects imported from leading brands in the world.

- Highly qualified and experienced staff

For any business, people are always the most important factor. Understanding this, NANOFRANCE attaches great importance to recruiting and training human resources. Thanks to that, NANOFRANCE owns a team of employees who are highly qualified, experienced and responsible towards customers. In particular, all employees are trained in skills to quickly update information on raw materials and the latest trends in the world's dietary supplement production.

- QA/QC quality management team : Understand the stages in the product processing process, check the quality of each production stage to always make timely adjustments.

- Customer service team : Not only have good professional knowledge but also very dedicated, always listen and answer all customer questions with a friendly and professional attitude.

- Packaging design team: Experienced in consulting for many famous brands, always promoting creativity in packaging design and product models.

- Strict quality control process

Since its establishment, the company's Board of Directors has set the principle of putting product quality first. Therefore, the quality control and assurance process is implemented extremely strictly. Each stage of production from input to output is closely monitored, meticulously monitored and promptly adjusted by the QA/QC department.

|

|

- Control from input materials:

NANOFRANCE has a periodic supplier evaluation process, only selecting and cooperating with suppliers that meet the following criteria: Good and stable quality, fast delivery progress and timely complaint resolution. If the raw materials do not meet quality standards, NANOFRANCE will not accept them.

Raw materials are sampled randomly to ensure that the test sample is representative of the entire batch. The sample is then preserved and sent to the testing room to test the necessary indicators according to NANOFRANCE's raw material standards compared with the supplier's COA. Testing includes qualitative, quantitative and microbiological testing. Currently, NANOFRANCE's testing room meets standards and masters the most modern testing methods such as HPLC, PCA... NANOFRANCE has a specialized storage area for each group of raw materials. All raw materials are preserved according to the recommendations specific to the characteristics of that raw material (cold storage, protection from light...).

- Production process control:

The QC team will take samples to test semi-finished and finished products. The samples are preserved and tested for quality. If any criteria are not met, the QA team will immediately propose a solution to handle that batch so that the product reaching consumers is always perfect.

- Perfect customer service

Customer service is also one of the criteria that NANOFRANCE puts on top. With the view of not only being a partner but also a companion in the success of customers, NANOFRANCE has proposed the most perfect services for customers.

– Exclusive formula consulting: Ensuring quality and unique factors, leading market trends.

– Support for product declaration registration: At NANOFRANCE, there is a specialized file room to help customers register quickly in just 3-5 days.

– Design consulting and packaging printing support:

The designers at NANOFRANCE are experienced and creative, ready to advise customers on beautiful and unique designs and support ordering product packaging at the most reputable units, so the packaging quality always ensures uniform and sharp colors.

- Research and test the effects of new strategic product lines

Researching and developing new, unique products to stay ahead of market trends is a highlight at NANOFRANCE. The R&D department with a team of experienced and creative pharmacists and experts is always at the forefront of researching new ingredients and new formulas, then testing their effects to create optimal formulas and strategic products for customers.

- NANOFRANCE owns a specialized raw material area and its own medicinal herb extraction area.

To strictly control product quality and take the initiative from raw materials to processing, the company's Board of Directors has invested in growing large raw material areas and building a modern herbal extraction factory.

|

|

With the above outstanding strengths, we are confident in creating pioneering and perfect quality functional food products for customers.

NANOFRANCE is the trusted companion of every customer!