The leading prestigious functional food factory in Vietnam

Functional foods are a rapidly growing manufacturing sector in the Vietnamese market. Functional food products are diverse in origin, design, quality, and type. Along with that, functional food companies and factories have been established one after another to meet the development needs of this sector. However, the question is "how can researchers and businesses choose a reputable functional food factory. From there, help realize ideas, create quality products, and serve the health needs of consumers?"

The article below gives you some suggestions to help you make the most accurate choice.

Concept of functional foods

Functional foods are foods that provide nutritional value and health benefits. Functional foods include nutrient-rich ingredients such as fruits and vegetables, and this category also includes foods that are known to enhance health and immunity such as vitamins, minerals, probiotics, and fiber.

Prestigious Functional Food Factory

Prestigious Functional Food Factory

Stages of functional food production

The production of functional foods includes three main stages: research, testing and product processing. Each stage requires strict requirements on human resources, professional qualifications, facilities, and machinery and equipment.

Product Research

Is the first step in the functional food production process. Based on the customer's idea about the product, the R&D department will conduct research on the main active ingredients of the product. The R&D department (Research and Development) is the department responsible for researching and developing new products. Helps meet market needs and the development strategy of the business.

The R&D department relies on practical production experience to build a preliminary formula for the product. Including the main ingredients that create the product's uses, the source of raw materials providing the main active ingredients, uses, users, etc. Next, conduct research to select raw materials. Then, mix the ingredients in the appropriate ratio, ensuring the uses of the active ingredients when combined in the same formula. Thereby maximizing the effectiveness of the product's uses.

Product Research

This stage requires the contribution of rich knowledge and experience. Especially experts and researchers in the fields of food, biology and medicine. A reputable manufacturing unit must have a truly strong R&D team in terms of knowledge base and creativity in product development.

Product Evaluation Testing of Functional Foods

After determining the ingredients and materials, the next step of production process is testing and evaluating the samples. From the complete construction formula, proceed to select the appropriate dosage form and process the test product. Each factory has the technology to produce different product forms, different capacities. Large manufacturers often meet the diversity of dosage forms and richness of product designs.

Testing and evaluation of dietary supplements includes assessment of clinical safety and efficacy. Conduct studies on stability, shelf life and effects of ingredients present in the product.

The product evaluation and testing stage requires modern analytical equipment. Researchers have experience and skills in product analysis. Evaluation methods require accuracy and reliability, according to Vietnamese and international standards.

Manufacturing

Functional food products with a defined formula, meeting safety and effectiveness testing standards will be put into production according to orders. Next, they will be prepared to be brought to the market to reach consumers.

The production scale of each factory is different, depending on the potential of that factory. At each stage of production, sampling and testing of semi-finished and finished products must be carried out. Samples are preserved and strictly tested for quality. Ensuring that the products delivered to consumers must meet the quality and product standards registered and approved by the competent management agency.

Processing functional foods at functional food factory

Thus, a reputable functional food manufacturing company must meet the conditions of high-quality human resources. In addition, the equipment must be modern. The production process must meet inspection standards. From there, valuable products can be created and trusted by customers.

Nanofrance - Prestigious Functional Food Factory

High-tech DP manufacturing company NANOFRANCE – Currently one of the few companies with systematic and strategic investment in the domestic functional food production market. NANOFRANCE is one of the pioneers in investing in the most modern machinery, equipment and technology in the production of functional foods. Nanofrance is proud to meet the demand for functional food processing and become a trusted partner .

Highly qualified staff

Highly qualified staff

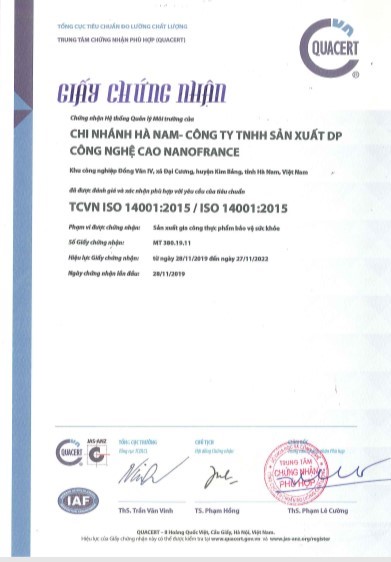

Possessing modern research and production equipment, a team of highly qualified and experienced researchers. At the same time, with a strict, modern and synchronous control process. NANOFRANCE is one of the first 10 functional food manufacturing companies recognized by competent authorities as qualified to produce functional foods. NANOFRANCE is recognized as meeting GMP and ISO 9001-2015 standards for the production and trading of functional foods.

Nanofrance is proud to be a reputable functional food manufacturer.

Nanofrance is proud to be a reputable functional food manufacturer.

Good Manufacturing Practice and ISO Certification

With the strengths of human resources, facilities, strategies and development principles of the company, NANOFRANCE is confident to be a reliable companion, meeting the requirements of all customers.

NanoFrance High Technology DP Production Co., Ltd.

Factory 1: Dong Van IV Industrial Park, Dai Cuong, Kim Bang, Ha Nam

Factory 2: Do Quan, Quat Dong, Thuong Tin, Hanoi.

Office: BT5 – Lot B6, Ha Dinh Urban Area, Lane 214 Nguyen Xien, Thanh Xuan, Hanoi

Hotline: 0986 859 777 – 0971220888

Email: duocnanofrance@gmail.com

COME TO NANOFRANCE TO FEEL FROM THE SMALLEST THING!